Glass Terminology

What is Float Glass?

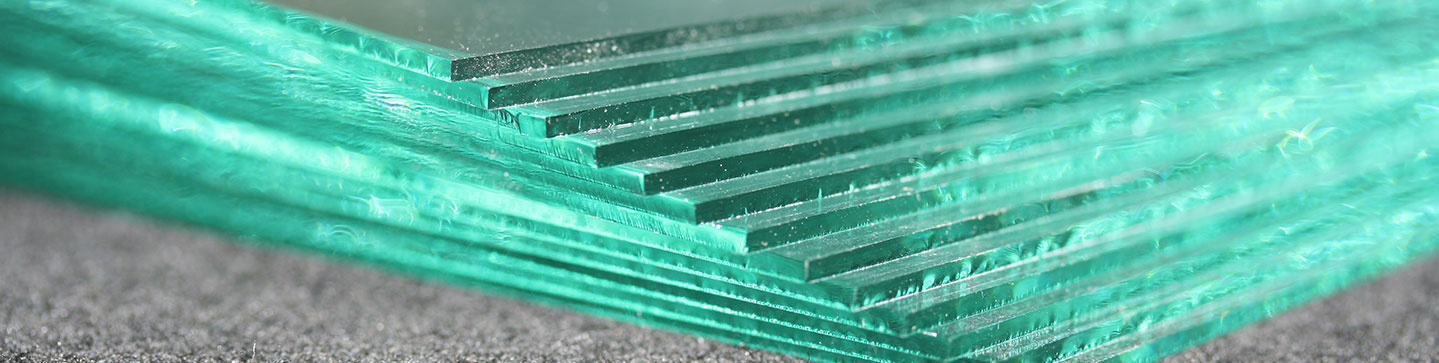

Glass produced by the Pilkington-invented Float system - which gives near-perfect, flat, clear glass from 1.25-25+mm in thickness. Float glass has almost completely replaced other forms (Sheet and Cast/Rolled glass) of flat glass production and is the base product from which virtually all other flat glass products are manufactured. Typically, 2mm float will transmit 90% of visible light, reflect 8% and absorb 2%. UV light filtering is approx. 45%.

What's the Difference Between Float & Sheet Glass?

Sheet glass is (was) produced by 'drawing' the molten mix through rollers to achieve the desired thickness of panel. This process left roller marks (areas of differing thickness) which caused the once familiar waviness. Sheet production virtually ended when the new float glass process was introduced in the 1970s. Float is produced by floating the molten raw material on a bath of molten tin. As the (continuous) ribbon of glass proceeds (floats) along the tin bath, it is cooled gradually until it has hardened enough to go off into a conveyor system (the tin remains molten at this stage) for cutting and packing.

As float is produced "liquid floating on liquid" it is perfectly flat and has a superb 'polished' surface finish. The float process invented by the British firm Pilkington, is frequently described as the most radical change to an industrial process since the war.

What Does 'Waterwhite' Mean?

Waterwhite is the term applied to float glass produced from material with very low metallic impurity levels. Standard float glass can vary between a fairly strong green and a pale turquoise colour (looked at from the edge of the panel). For most applications, this range of colouration is perfectly acceptable but for critical uses (optical instruments, museums etc) a much lower colouration level is required.

What is Low Reflection or Anti Reflection Glass (AR)?

Float glass with several layers of various metallic oxides on both surfaces. These coatings (known as Optical Interference Coating) dramatically reduce surface reflections by allowing very high visible light transmission through the glass. Visible light reflection is less than 1% and transmission can be well over 98% - particularly when a Waterwhite glass substrate is used. The same coating technology is employed for high-end spectacle, binocular and camera lenses. Designed to give optimum clarity to the artwork, these glasses should be used under good lighting conditions to give their full benefit. Used properly, they give huge improvements to image brightness, contrast and colour resolution. Not intended for use in harsh lighting, typical examples are: Tru Vue Ultravue® and TruVue Museum®, Schott MIROGARD® and Artglass AR.

What is Diffused-Reflection Glass?

Also known (in USA particularly) as "non-glare" and, incorrectly, as non-reflecting glass, these are glasses with one or both surfaces altered to scatter or diffuse the reflected portion of visible light. This gives a much wider viewing angle to artwork - particularly under harsh lighting. It does reduce image contrast and clarity --particularly if used over mountcard(s). Two methods of surface alteration are used:

i. Acid-etching

ii. Casting/Rolling.

The acid-etching process gives generally better results with the cast/rolled glass being used for bulk and lower-priced work.

What is Safety Glass?

Glass altered in such a way as to reduce the risk of personal injury to the end user and the public. There are two main types, toughened and laminated. Toughened glass is usually used where there is a high risk of impact and stress damage, as it is significantly stronger than plain glass. When broken, it disintegrates into small, relatively harmless, granular particles. Laminated glass is used for large panels where an element of security is required. Laminated glass is no stronger than plain glass but, due to the plastic interlayer, retains a high degree of structural integrity when damaged. Typical uses for toughened glass are: table tops, shelves, counter tops and panels, door and window glazing. Laminated glass is used in shopfronts, car windshields and high security panels. Both have limited applications in picture framing, but laminated glass can be produced to combat UV damage and, in very specialised forms, is widely used in Museums.