Glass Handling & Cutting

How Do I Cut Glass?

Depending on space available and preference - either on a cutting bench or a wall-mount system (see Keencut or Fletcher). In either case, it is best to use a proper, tungsten carbide cutting wheel, rather than a cheap 'DIY' store one, or a diamond. Glass to be cut should be dry and warm (i.e. above 55°f / 12°c) for reliable results. The cutting wheel should be kept free of dirt and dust build-up and lubricated as recommended by the supplier. Always use a proper T-square or straight edge and cut smoothly across the sheet from edge to edge. Do not go over the cut again. Always break out the cut quickly - the longer it is left the less reliable the result will be. With a wallmount cutter, take great care to avoid the glass coming into contact with hard surfaces when loading/unloading. With a bench, make sure you keep the (felt or carpeted) top surface free from shards of glass etc. When starting to use a new hand-cutter, lubricate it as recommended and cut up some scrap glass/offcuts for a few minutes to run the wheel in properly. When cutting coated glass, pay particular attention to cleanliness and ensure that you are cutting the correct side of the glass if applicable.

Is it difficult to cut speciality glass?

Cutting all of our speciality glasses (other than laminated products) is no different to cutting ordinary glass, as long as three points are observed:

1. Certain coated glasses such as TruVue Conservation Clear should only be cut on the uncoated side (if unsure check the manufacturers instructions)

and

2. When cutting speciality products, take great care to keep your bench free from shards of glass, debris etc by frequent sweeping or vacuuming

and

3. Do not slide the glass on or off the bench - lift it carefully to minimise the risk of scratching. If using a wallmounted cutter, take great care to avoid allowing contact between glass and metalwork when loading/offloading the glass. (These comments apply equally to ordinary glass too - and if followed will practically eliminate glass damage during cutting.)

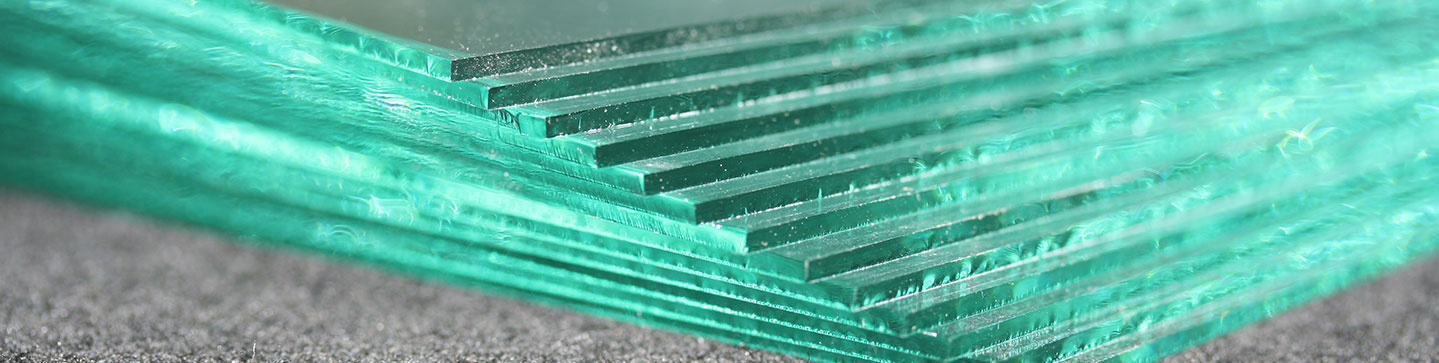

How Should I Store Glass?

Full sheets of glass should be stored upright (on-edge) at approx. 5° angle against a supporting structure. It should stand on timber/MDF or similar material (never concrete/masonry etc.) and should rest against a felt or carpet - covered structure. Storage conditions must be dry and ideally at workshop temperature. Glass stored in cold conditions will have condensation problems when brought into a warmer working area. It will also be significantly more difficult to cut. Glass stored in damp conditions will rapidly deteriorate and can become unusable due to water or paper staining in a surprisingly short time. Even in ideal conditions, stock sheets of float and diffused glass should be rotated regularly to avoid possible problems. If you must store glass for long periods (say six months+) keep it warm and dry - and remove the paper interleaf. The same rules apply to cut-to-size glass except that, with care, this can be stored flat although this practice is not recommended.